Guangzhou Factory Plastic Nylon PA Polyamide Gear Rack

**Plastic Nylon PA Polyamide Gear Rack Supplier from China**

Looking for a reliable supplier of plastic nylon gear racks? Guangzhou Engineering Plastics is your ideal partner. Our high-quality nylon gear rack products are manufactured using advanced engineering plastics technology and are suitable for a wide range of industrial applications.

**Basic Product Information:**

- **Model NO.:** Nylon Gear Rack

- **Color:** Natural, White, Black, Green, Blue, Yellow

- **Shape:** Tube, Sheet, Parts, Gear, Gear Rack, Pulley, etc.

- **Application:** Food & Beverage Industry, Light Industry, Electronics

- **Free Sample:** Available

- **Delivery Date:** 15–25 Days

- **Transport Package:** Plastic Case, Carton, or Customized as Required

- **Origin:** Guangzhou, China

- **Size:** Customized according to Drawing or Sample

- **Density:** 1.2

- **Brand:** Engineering Plastic

- **Certification:** RoHS, FDA, etc.

- **Warranty:** Yes

- **Trademark:** Guangzhou Engineering Plastics

- **Specification:** RoHS

- **HS Code:** 3926909090

**About MC Nylon:**

MC nylon, also known as Monomer Casting Nylon, is an advanced engineering plastic widely used across various industries. It is produced by casting caprolactam monomers under atmospheric pressure, resulting in high molecular weight (70,000–100,000 g/mol), which is three times higher than that of PA6/PA66. This gives it superior mechanical properties, making it a preferred choice in many industrial applications.

Since the late 1980s, Guangzhou Engineering Plastics has been dedicated to developing modified MC nylon technologies, significantly expanding its use in different sectors. By adding various additives such as lubricants, molybdenum disulfide, graphite, glass fiber, and carbon fiber during the reaction process, we enhance the material’s wear resistance, corrosion resistance, self-lubrication, vibration absorption, and noise reduction capabilities. The simple mold design also allows for cost-effective production, making it a great alternative to materials like bronze, stainless steel, babbitt alloy, and PTFE.

**Oil Nylon (Green):**

Developed by Guangzhou Engineering Plastics in the late 1980s with advanced technology from Nylacast Co., Ltd. in the UK, Oil Nylon is the first authentic lubricating nylon that incorporates a liquid lubricant system during processing. This reduces the coefficient of friction by 50% compared to standard PA6 or PA66 and increases wear resistance by 10 times. It's especially suitable for non-self-lubricating, heavy-load, low-speed parts, significantly extending bearing life—up to 5 times longer than PA6 and 25 times longer than phosphor bronze. The internal lubricant remains stable, never dries out or needs reapplication, ensuring consistent performance over time.

**Other Casting Nylon Variants:**

- **Oil Nylon + Carbon (Black):** Offers enhanced mechanical strength, wear resistance, UV resistance, and anti-aging properties, ideal for bearings and wear parts.

- **Oil MC901 (Blue):** Improved MC nylon with excellent toughness, flexibility, and fatigue resistance, perfect for gears, gear bars, and transmission components.

- **MC Nylon + MSO2 (Light Black):** Enhances impact and fatigue resistance while improving load capacity and wear resistance, suitable for gears, bearings, and seals.

**Material Properties Table:**

| Property | Item No. | Unit | MC Nylon (Natural) | Oil Nylon + Carbon (Black) | Oil Nylon (Green) | MC90 (Blue) | MC Nylon + MSO2 (Light Black) |

|----------|----------|------|--------------------|----------------------------|-------------------|-------------|-------------------------------|

| Density | 1 | g/cm³ | 1.15 | 1.15 | 1.135 | 1.15 | 1.16 |

| Water Absorption (23°C in air) | 2 | % | 1.8–2.0 | 1.8–2.0 | 2 | 2.3 | 2.4 |

| Tensile Strength | 3 | MPa | 89 | 75.3 | 70 | 81 | 78 |

| Tensile Strain at Break | 4 | % | 29 | 22.7 | 25 | 35 | 25 |

| Compressive Stress (at 2% nominal strain) | 5 | MPa | 51 | 51 | 43 | 47 | 49 |

| Charpy Impact Strength (unnotched) | 6 | KJ/m² | No break | No break | ≥50 | No BK | No break |

| Charpy Impact Strength (notched) | 7 | KJ/m² | ≥5.7 | ≥6.4 | 4 | 3.5 | 3.5 |

| Tensile Modulus of Elasticity | 8 | MPa | 3190 | 3130 | 3000 | 3200 | 3300 |

| Ball Indentation Hardness | 9 | N/mm² | 164 | 150 | 145 | 160 | 160 |

| Rockwell Hardness | 10 | - | M88 | M87 | M82 | M85 | M84 |

Whether you need custom-designed parts or standard components, Guangzhou Engineering Plastics offers high-performance, durable, and cost-effective nylon solutions tailored to your specific requirements. Contact us today for more information or to request a sample.

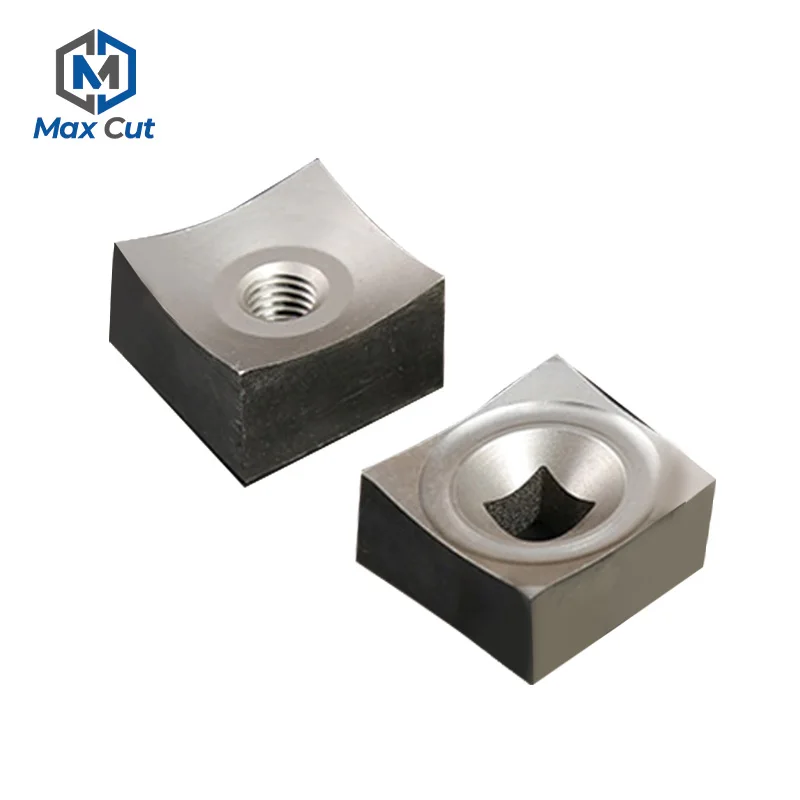

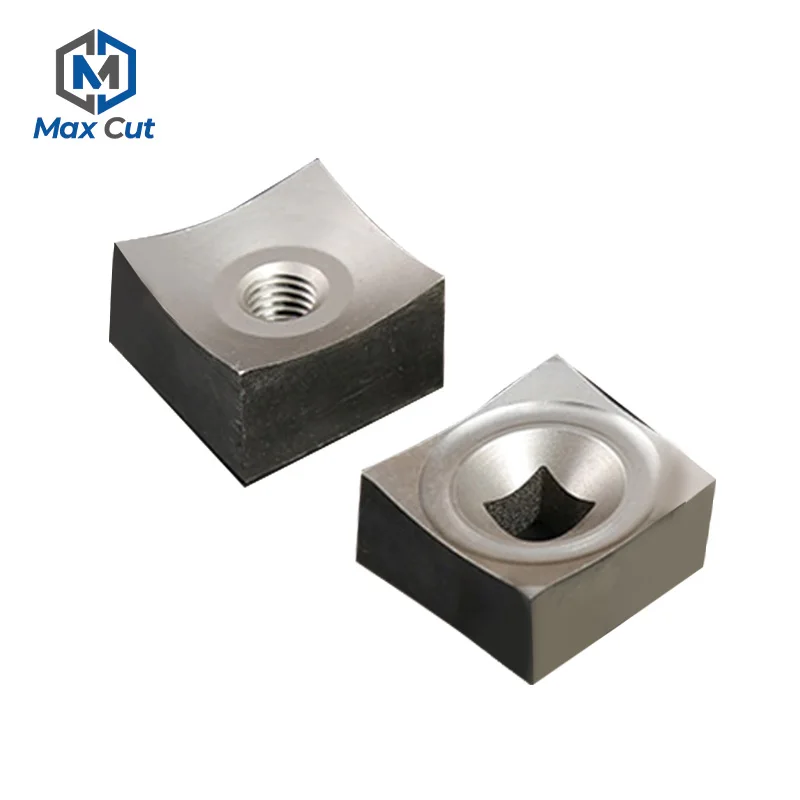

The advantage of a shredder blade lies in its ability to efficiently and effectively cut, shred, or pulverize materials into smaller pieces. It is designed with durability and sharpness to withstand heavy-duty tasks, making it suitable for a wide range of applications such as waste management, recycling, and material processing. The blade's unique structure and hard-material coating ensure precise shredding and minimize wear and tear, leading to increased productivity and reduced downtime.

The advantage of a shredder blade lies in its efficiency and durability for shredding materials. However, its application is limited by the material's toughness and density, as certain materials may require specialized blades or increased power to shred. Additionally, smaller or fragile items may be damaged by the intense shredding process.

Single Shaft Shredder Blade,Double Shaft Shredder Blade,Plastic & Paper Crushing Blade

LLY PACK(foshan) Co.,Ltd. , https://www.llypack.com